Replacing the Automatic Transmission Pan Gasket

Joe Angell

My automatic transmission seems to always leak. I've gone through three transmissions in the last decade and a half, and they aren't cheap. Although one was a failed weld, it seems likely that the others were due to leaking transmission fluid that I didn't notice until it was too late and burned out the clutches.

While I was replacing my engine, I decided to take care of the transmission pan gasket with a new one provided by DeLorean Performance Industries. The original gaskets are cork, and are not terribly good. DPI's gasket is a much more robust silicone design that should be much less prone to leaks. I did the replacement right after I put the engine and transmission back in the car. I probably could have done it out of the car, but I didn't feel like getting it onto an engine stand and flipping it over or crawling under it.

Raising the Car

Mine was already raised as part of the engine swap, so this step was already done. Just remember you'll need to roll under the car from the back to get to the pan, and to use jack stands or pallets/stands under the wheels to ensure the car doesn't fall on you.

Draining the Transmission

The transmission drain plug is mounted on the pan towards the front of the car. It requires the same 8mm square plug that the engine oil pan uses. With the back of the car raised, you should be able to get most of the fluid out, but probably not all of it.

Be aware that you will not get all the fluid out. The torque converter holds on to fluid, and simply jacking up the car higher after draining could cause more fluid to shift into the pan. I had drained mine before removing the engine/transmission and had recently reinstalled it, but didn't think to drain the transmission again. When I took of the pan in the next step, I emptied around half a gallon onto the floor.

The point is, even if you think the transmission is empty, you should probably drain it again just to be sure.

Removing the Pan

Before you remove the pan, you may want to consider taking off the bracket that holds the coolant pipes under the car. The pane sits under one of the pipes, and can be pretty tough to get past them without tipping it. If there is any fluid left in the pan, you will spill it. I, of course, did not do this, and spilled quite a lot of fluid on my floor.

There is a ring of bolts holding the pan to the transmission. They are all the same length, and need an 11mm socket for removal. Mine were remarkably loose, so much so that I barely needed the wrench to break them free; I just used a power screwdriver with a socket adaptor and had them off in no time. After removing the last bolt, the pan might stick to the transmission or it might fall, so be prepared (mine fell, but I could see that it was going to as I started loosening the last bolt. To get the pan clear of the transmission you'll have to fiddle to maneuver it past the coolant pipe without tilting it too much and getting whatever fluid remains in it everywhere as I did. I dumped out whatever fluid was left in the pan and wiped out the inside with some shop paper towels.

Removing the Old Gasket

My gasket stuck to only the pan, and not at all to the transmission. This meant that I only really had to clean the pan itself. As with my engine repairs, I used plastic tools to scrape the old gasket material off. Since the pan is steel, you can use razors without worrying as much about nicking the metal as compared to removing gaskets from the softer aluminum engine. I got as much of the gasket off as I could without spending a huge amount of time on it. Overall, it came off pretty easily with the plastic tools and a bit of razor blading to remove some of the remaining residue. I detail how I removed a much rougher gaskets in the blog posts about the oil pan and engine covers; the same techniques should apply here as well.

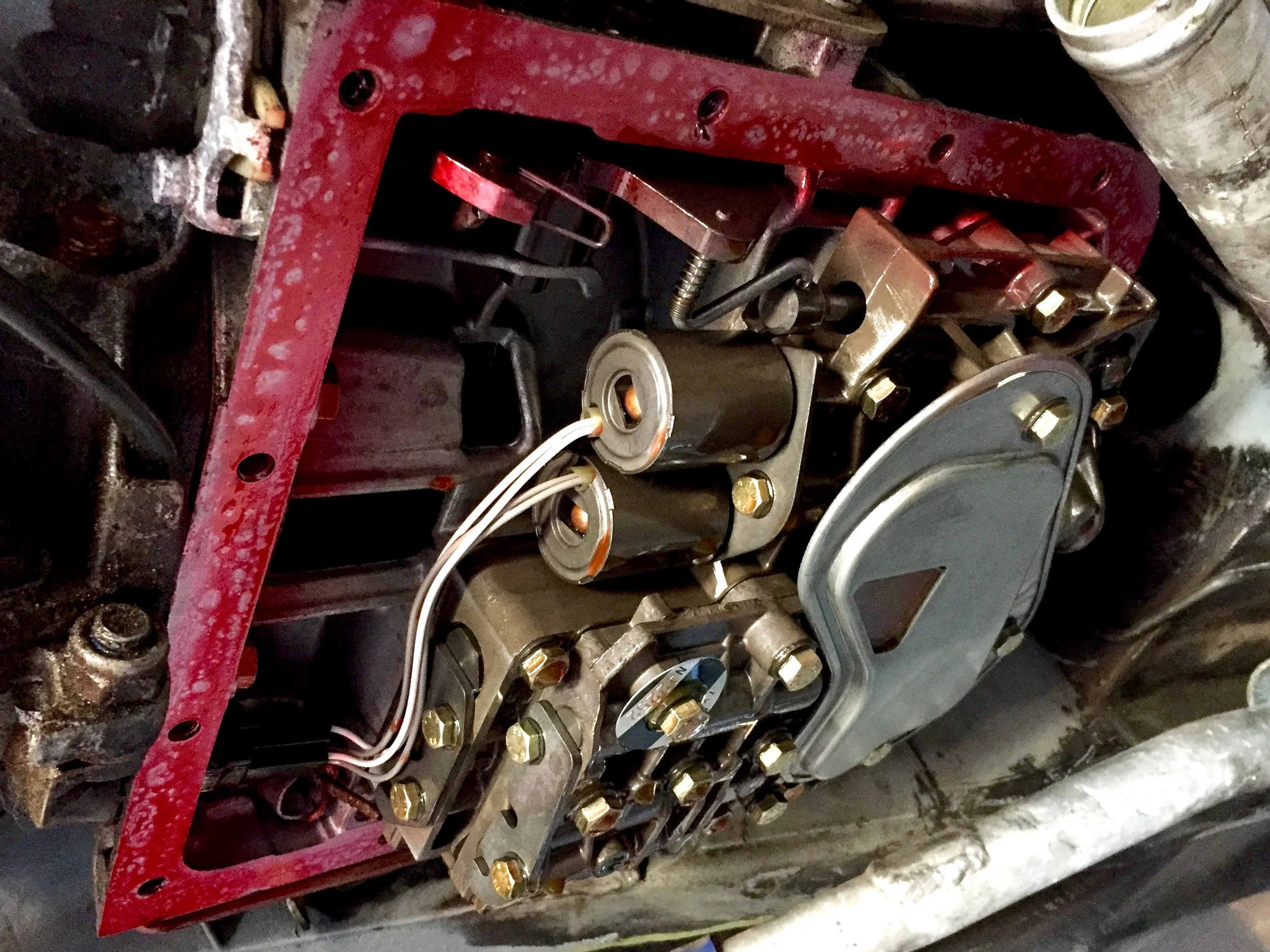

Replacing the Transmission Filter

While you have the pan off, you might want to replace the filter. Mine was quite new, so I didn't bother with it, but if no one has been in there in a while this is a good time to do it.

You should also check the magnet for metal bits. Usually this is stuck to the pan near the drain plug, but mine was stuck to the filter. I was a bit disturbed to find mine covered with small pieces of metal, considering how new my transmission was. I was mostly hoping that it simply hadn't been cleaned before being put in the new transmission or something. I cleaned it off and mounted it in the bottom of the pan.

Installing the New Gasket

I wasn't really sure about using any sealant or RTV on the silicone gasket. I decided to treat it like the engine oil pan and applied a coat on Permatex High-Tack Sealant (the spray kind, 80064) onto the pan's mating surface, placed the gasket, and then applied another coat to the gasket itself before putting it back in the car.

Spray sealant applied to the pan. The gasket was placed on top of it after letting it set up for a minute or so.

Spray sealant applied to the transmission's mating surfaces.

Reinstalling the Pan

The pan goes back in the way it came out. The spray sealant kept the gasket mostly in place, which made reinstallation easier. I used my power screwdriver with an 11mm socket on an adaptor to get the bolts most of the way in. They are torqued to a remarkably low 2-3 ft lbs, which probably explains why I found them so easy to remove. My smaller torque wrench wasn't labeled that low, but I was able to turn it past the labeled minimum to something in that range. Be very careful not to over tighten them, or you could bend the pan and will have even more leaks than you may have before.

Installing the bolts with an 11mm socket on a power screwdriver.

Torquing the bolts to the remarkably low 2-3 ft lbs specced from the Workshop Manual.

That's it -- you should now have a leak-free pan.